T: +44(0)161 883 2247

E: office@aail.co.uk

Drill Alignment Systems

4-Pad Configuration for ADU usage

The main DAS335 unit

DAS335-SP and RT-1 transmitter on charge

Portable Vacuum Pump

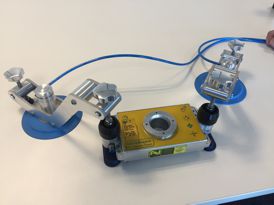

DAS335-SP compact configuration

Heavy duty external vacuum pad accessories for DAS335-SP

Heavy duty mechanical clamp accessories for DAS335-SP

DAS-Atom system

DAS-Atom unit

There are multiple datasheets;

DAS PVP Portable Vacuum Pump datasheet

We also have a video covering some of the product range and demonstrating the system.

One of the most time consuming activities in aerostructure manufacture and repair is the location of buried fastener holes and the subsequent alignment and drilling of the corresponding hole in the aircraft skin.

Traditionally this has been achieved by back drilling a pilot hole and then re-drilling through the top surface. This approach is both time consuming and inaccurate especially where either space is restricted or where the distance between the surface and the pilot hole is large, a particular problem in carbon structures.

The DAS335 Drill Alignment System consumes a meagre 400mW of power and consequently will run continuously for 10hrs from a single 2hr charge of its internal batteries. In its standard configuration, it is capable of finding a buried pilot hole centre to within 0.5mm, which is the accepted norm for aerostructure production.

Following on from our work of 2001 for the Eurofighter project we were able to utilise the same sensor technology and analysis techniques to develop the smallest and most accurate drill position system currently available.

Our innovative non hall effect detection system eliminates the frequent calibration requirements and sensitivity to local fields of that technology. Our solution is a series of robust self contained portable, battery operated units that utilise a variety of fixing methods. At the most simplest they use cam operated suction pads or mechanical clamps to fix the unit to the structure, and where these are unsuitable a range of vacuum actuated mechanisms are available, using self contained battery powered vacuum pumps.

The unit is very simple to operate with four multicoloured direction indicators. Some units posses vertical and horizontal vernier controls or a joystick for finer positioning after clamping the unit to the surface in a location determined using a coarser positioning mode. This two step process allows deep hole positioning far exceeding any other devices on the market.

Product Specifications

| Dimensions |

|

||||||||||||

| Range | 5mm - 200mm | ||||||||||||

| Accuracy | 0.5mm | ||||||||||||

| Power | 400mW from internal rechargeable battery | ||||||||||||

| Endurance | 10 hours from single charge | ||||||||||||

| Recharge time | 2 hours |